Cross flow cooling towers

Product Details:

- Size Standard

- Color Gray

- Material PVC

- Usage Industrial

- Condition New

- Click to view more

Cross flow cooling towers Price And Quantity

- 100 Sheet

- 3300 INR/Sheet

Cross flow cooling towers Product Specifications

- Gray

- Industrial

- Standard

- PVC

- New

Cross flow cooling towers Trade Information

- 5000 Sheet Per Month

- 1 Week

Product Description

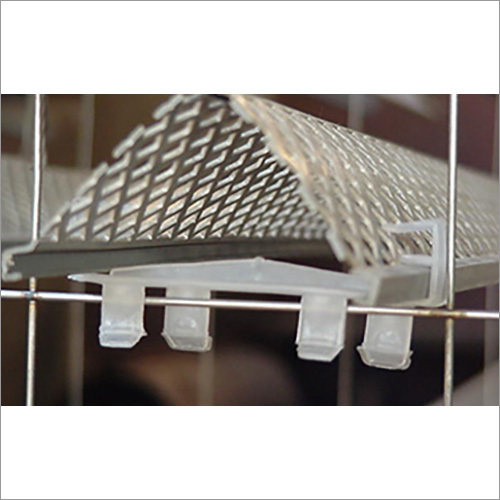

Film Fills for Crossflow Cooling Towers (CD-XF Series)

Splash fills such as V-Bars, lathe, grids, triangular bars and rectangular bars manufactured in PVC/PP are the common fill solutions for crossflow cooling towers. These splash fills are non-clog type but lack the efficiency of film fills.

High efficiency film fills employ the cross-fluted design and assembly pattern. Interestingly the cross fluted design was first conceived for use in Crossflow cooling tower applications but has since been found to be of greater use in their Counterflow counterparts. Film Fills offer much greater efficiency than splash fills as a result of greater water exposure to air per unit volume of fill.

Film fill Crossflow media includes the 'curtain type' fill media that consists of an assembly PVC sheets of up to 12' in height hanging close to each other across the length of the tower. Crossflow film fill sheets often include specially designed flutes formed with the sheet which function as inlet louvers and drift eliminators when the sheets are positioned into modules.

COOLDECK has developed its own modular Crossflow film fill series - CD-XF. As the name describes these are film fill modules, rather than individual sheets. The flute angle on these sheets has been chosen to account for the change in water angle due to the opposing air stream at different velocity (Crossflow configuration)

The resultant fill block thus creates continuous passage for water to travel downstream through the fill surface while creating various paths through the fill geometry for the air to travel through the fill media and thus resulting in efficient heat exchange.

Drift eliminators and inlet louver sheets are integrated into alternate layers of this fill. The inlet louvers guide the airflow into the tower system while the drift eliminators ensure miniscule loss of water. The efficient design of these two components ensures saving of various resources such as fan horsepower and make-up water (and related chemical treatment costs). The integral system eliminates the support cost associated with discrete drift eliminators and inlet louvers installations.

The modular construction of the CD-XF fill media makes it easier to maintain the fill media. Maintenance can be performed on individual modules rather than bring the entire suspended assembly down.

Specifications

Manufactured using virgin PVC, the material used for CD-XF series exceeds all the minimum standards for physical properties of material as specified by CTI-STD136. Various configurations are available to cover heat exchange area in the fill between 18" to 48" (excluding drift eliminator and inlet louver). These can be installed in new Crossflow towers as well as retrofit applications. The heat transfer (wetted surface) area for the CD-XF series is 158 m2/m3 (48 ft2/ft3)

These fills can be used as an economic replacement of suspended type of fills of Sigma/Aquai towers. For Sigma replacement, check the depth of fill (air travel) and choose the appropriate model from the above table. The height of Sigma fill installation is to be achieved by placing the '600-mm high' CD-XF modules one above the other. The tower will be filled width wise by placing the '300-mm wide' CD-XF blocks adjacent to each other.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese