Counterflow cooling tower

Product Details:

- Size Standard

- Material PVC

- Usage Industrial

- Color Gray

- Condition New

- Type Cooling Tower

- Click to view more

Counterflow cooling tower Price And Quantity

- 750 INR/Square Meter

- 1000 Square Meter

Counterflow cooling tower Product Specifications

- Industrial

- Gray

- Cooling Tower

- Standard

- New

- PVC

Counterflow cooling tower Trade Information

- 5000 Square Meter Per Month

- 7 Days

Product Description

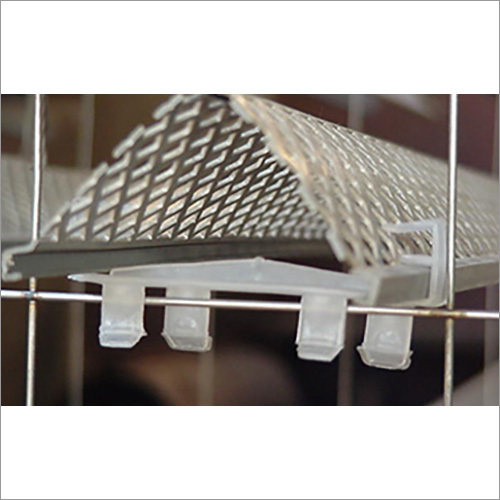

Film Fills are the most efficient filling media available for cooling towers. The usage of film fills - in both counterflow and crossflow cooling towers allows relatively smaller sized towers to cool an equivalent amount of water compared to cooling towers using splash fills. This results in the saving of not only capital costs for a new tower but also reduces operational costs on account of lower height and hence lower pumping costs.

Film Fills work on the principle of offering heat exchange by spreading the falling water droplets into a thin molecular film where the air can effectively contact the entire surface of the water film to carry away heat and mass.

Advantages:

Minimum resistance to air flow

Good distribution of water leads to turbulent mixing of air and water to maximize heat transfer.

Reduced fill height and greater cooling capacity results in lower power consumption.

Erosion and rotting resistant and long lasting (10-12 years of service time in good quality water)

Self-supporting, high strength and self-extinguishing characteristics

Resistance to weather exposure (fungii oxidation) Nearly impervious to chemical degradation by Alkali, acid, grease, fats, oils and biological attack

Easy to glue at site, reduces transportation cost.

Sheets manufactured by Calendaring system have advantages of polymers being blended perfectly with negligible thermal degradation, yielding a uniform thickness fill sheet having superior mechanical and physical properties.

Disadvantages of Blown Film line:

Poor finish

Varied sheet thickness

Improper blending

Thermal degradation

Although the conventional manufacturing of sheets comply to CTI 136, the quality is inferior as compared to sheets manufactured by Calendaring system.

ADVANTAGES OF STRAIGHT FLUTED FILLS:

Cross fluted films are considered to be the most efficient fills.

In India the water quality is not very good, this leads to clogging of fills after a very short span of time (8-10months).

COOLDECK has developed vertical fluted fills which are resistant to clogging.

Although cross fluted fills have an efficient design, straight fluted fills are highly recommended due to its long lasting life.

COOLDECK offers a combination of cross fluted fills at the top and vertical fluted fills at the bottom that gives the combined advantages of both type of fills thus reducing the entire clogging on the fill significantly and giving good cooling efficiency.

Factors to keep in mind while selecting the right Fill:

Film manufacturers must have their own in house calendaring manufacturing process as this is the most advanced technology to manufacture superior quality sheets that exceeds the requirements of CTI 136.

Many of the conventional Fill suppliers claim to procure sheets manufactured by Calendering process, but these sheets are often procured from suppliers that use Blown film line process which confirms to CTI 136.

It is important that the thermal coefficients of the fill are available. There are a number of copycats that may have copied the product to the best of their abilities but the user must realize the nature of this product is technical and no copy cat will be able to capture all the design nuances of a product. Fills when procured from such copy cat vendors may not give the necessary thermal results. Furthermore by indulging in such low technology vendors, customers are discouraging engineering thereby causing disservice to R&D and deterring new product developments.

The Fills must have inbuilt Gluing points at specific points in order to reduce the consumption of glue and not creating obstacles to the micro structure, thus allowing proper channeling of water.

Straight Fluted fills must have proper distribution at the top so that the water does not fall through freely.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese