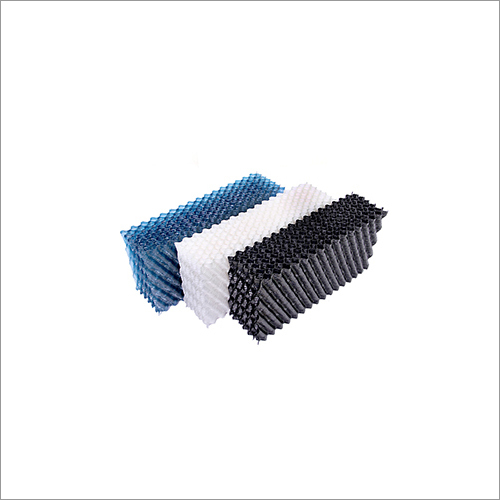

Pvc Film Fills

Product Details:

Pvc Film Fills Price And Quantity

- 3500-5500 INR/Cubic Meter

- 50 Cubic Meter

Pvc Film Fills Trade Information

- 1000 Cubic Meter Per Week

- 2 Week

Product Description

PVC Film Fills are one of the most efficient filling media which is present for cooling the towers properly and effectively. These fills are made using honeycombed PVC film which ensures proper water distribution and high efficiency water to air heat transfer. These fills are best known for its quality, durability, great cooling capacity, light weighted, eco-friendly, reduces water wastages and economical to use and easy to handle. PVC Film Fills also help in reducing the fill height as well as transportation and maintenance costs. These fills require low power consumption hence less amount of energy is preferred for better cooling.

Technical Specification

| Characteristics | CD-19 |

| Primary Cooling Towers Application | Counterflow |

| Flute height | 19 mm |

| MOC | Virgin rigid PVC |

| Longitudinal pitch | 50 mm |

| UV Stabilization | White Titanium Dioxide |

| Spiral angle | 28 |

| Std. Sheet sizeL x W | 1200mm x 600mm |

| Recommended Max Fill Sheet size L x W | 1800 mm x 600 mm |

| Surface area per unit volume | 158 m/m |

| Standard Weight | 27 Kgs/m3 |

| Maximum continuous Operating temp. | 55 C |

| Standard Fill Sheet Finished Thickness (Available in 0.23mm thickness Other thickness on request) | 0.25 mm |

| Standard Followed for Material properties | CTI STD-136 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese